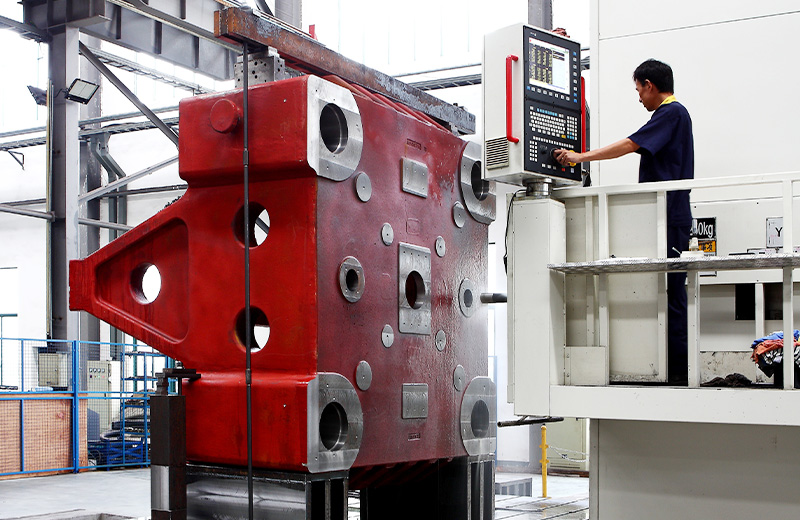

SONLY is a high-tech enterprise specializing in providing integrated solutions for plastic molding. Founded in 1998 and located in Ningbo, known as the "Capital of Injection Molding Machines in China," the company integrates R&D, manufacturing, processing, testing, and application, with an annual production capacity of 5,000 units. SONLY operates a modern production base covering 60,000 square meters, equipped with over 300 large-scale advanced precision machining and testing devices. The company employs a highly skilled and educated team for technical R&D and management, and has established a joint graduate training base with renowned universities.

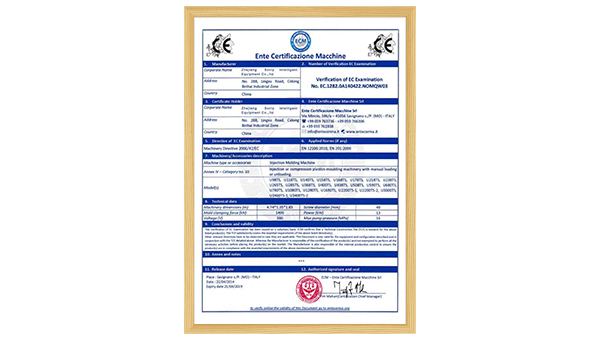

SONLY is recognized as a model enterprise for machinery brands by the Ministry of Industry and Information Technology. Certified with CE and ISO9001 quality management systems, the company has accumulated 33 authorized patents. Its product portfolio includes the F9 Supersonic Series, C8 Classic Series, U-TSDK Large Two-Platen Series, U-TSEK All-Electric Series, U-TSDH Single-Cylinder High-Speed (Electro-Thermoplastic) Series, and UTS Series, among other precision servo injection molding machines. With a clamping force range from 98 to 3,400 tons, SONLY has established over 100 sales outlets across China, and its products are exported to regions including the Middle East, South America, Europe, North America, Southeast Asia, and Africa.

-

0

Founded in

-

0 m²

Company Area

-

0 +

Employees

-

0 +

Annual Production (Units/Sets)

-

Corporate Vision

SONLY injection molding machines aim to become the "primary productive force" for customers through technological strength, taking responsibility for customer value and creating sustained and substantial benefits. -

Corporate Mission

The global mission of SONLY is to explore new pathways for high-quality enterprise development with new quality productivity at the critical point of "green, low-carbon, and intelligent" transformation in the plastic molding industry. The company strives to transition from a regional cost-effective supplier to a global provider of system solutions, ultimately becoming an "innovator in global plastic molding technology and a leader in low-carbon intelligent manufacturing." -

Corporate Values

For three decades, SONLY has adhered to the product philosophy of "efficient energy saving, precision, and stability," committed to providing globally advanced, functional, and reliable equipment for customers in the plastic products industry, along with cost-effective, low-energy, and personalized integrated plastic molding solutions. "Innovation, green, intelligence, openness, and energy efficiency" define our brand philosophy. The company upholds the values of "integrity, responsibility, pragmatism, innovation, and altruism," serving numerous users and creating enhanced value.

We provide comprehensive technical and commercial support from model selection to full project implementation:

Model Selection Consultation: Assist customers in selecting suitable equipment based on product dimensions and offer integrated intelligent solutions including molds and auxiliary machinery.

Documentation Support: Supply technical specifications, test reports, parameter manuals, certification documents, and other relevant materials.

Maintenance Services: Respond to customer service requests within 24 hours to ensure uninterrupted machine operation.

- Over 300 sets of large-scale precision machining and testing equipment, including imported advanced models.

- Annual production capacity reaches 5,000 units/sets.

- Equipped with advanced processing and inspection facilities for in-house manufacturing, ensuring high part precision, short lead times, and the ability to meet high-standard customized requirements.

English

English  Français

Français

+86-400-8120-669

+86-400-8120-669  sales@ouyilai.com

sales@ouyilai.com

No. 288 Lingxu Road, Cixi Coastal Economic Development Zone, Ningbo, Zhejiang, China

No. 288 Lingxu Road, Cixi Coastal Economic Development Zone, Ningbo, Zhejiang, China